How temperature affects longevity of LED luminaires?

As a rule, high ambient temperature reduces the efficiency and durability of lighting fixtures, including LED fixtures. Its impact can be significant both on light sources and batteries powering emergency systems. Equally destructive are temperature fluctuations, which can lead to faster component degradation, reduced light output, and shortened operational lifespan of lighting fixtures. Here’s what to consider when selecting fixtures for challenging temperature conditions.

How to minimize the impact of temperature on LED fixtures

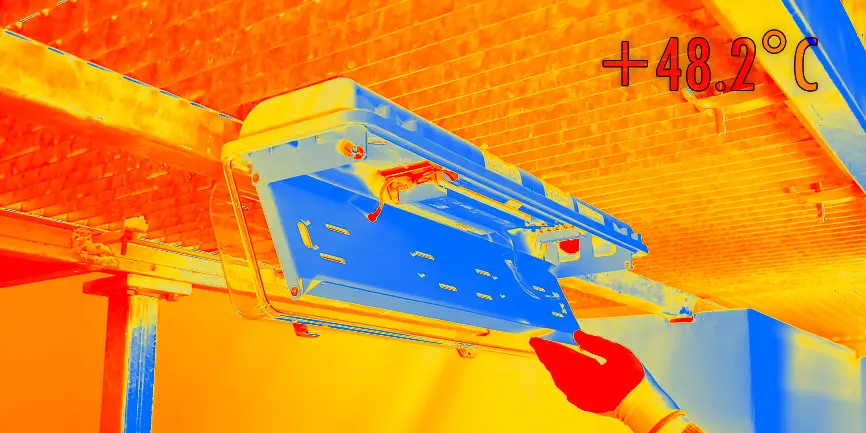

The negative impact of temperature on LED modules, as well as batteries used in emergency fixtures, is typically mitigated through design solutions. Another approach is the optimal selection of electronic components and their operating parameters. For example, we applied this solution in the OptiLine fixture, which is intended for installation in explosion-hazard zones over a wide temperature range of -40…+50oC. Importantly, the ability to use the fixture in such a wide temperature range has been confirmed through internal research as well as a series of tests in an accredited laboratory. These tests involved analyzing the device’s operating parameters during prolonged heating.

The OptiLine fixture is dedicated to harsh and very harsh conditions, which in practice means constant or frequent exposure to moisture, chemical factors, dust, UV rays, and mechanical damage. Such working conditions required the use of a solid, thick-walled body. This solution also serves as thermal insulation, protecting the fixture from excessive heating due to external factors (sunlight, hot surfaces, etc.) while limiting the heat emission generated by the internal electronic components. Therefore, our R&D department designed the operating point of the fixture in such a way as to minimize the heating of electronic components, including LED modules and the power supply.

This was achieved by increasing the lighting efficiency of LOW/MID Power LED modules through specific LED diode polarization while setting the power supply operation below nominal parameters. As a result, we significantly reduced the amount of generated heat and increased the lifespan of electronic components, including the mentioned LED modules.

Location of fixture vs. operating temperature

Considering workplaces utilizing artificial lighting, there is a need to create products increasingly better suited to the specific environment and climate in which they are used. In this regard, two main groups of factors can be distinguished, where ambient temperature plays a key role:

- location within the facility,

- geographical location

| Climate zone | Average annual air temperature | Temperature amplitudes |

| Equatorial | Above 20°C | 5-10°C (annual average) up to 10°C (daily) |

| Tropical | Above 20°C | 10°C (annual average) up to 40-50°C (daily) |

| Subtropical | 10-20°C | 10-15°C (annual average) up to 50oC (daily) |

| Temperate | 0-10°C | 25-35°C (annual average) up to 30oC (daily) |

| Polar | Below 0°C | up to 80°C (annual average) |

Impact of operating temperature on lighting fixture selection

Typical locations where temperature is crucial for lighting fixtures:

- production installations, especially processes emitting heat (boilers and furnaces, reactors, mills, welding equipment, hot media transport, etc.),

- outdoor spaces, especially with direct sunlight exposure,

- industrial and warehouse halls, especially roof installations,

- cold storage facilities,

- underground mining installations.

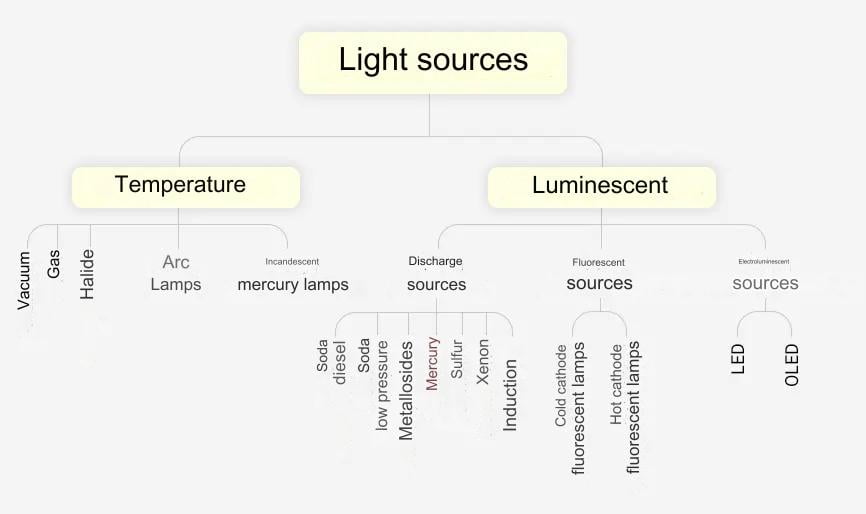

Figure 1 shows the classification of electric light sources based on their production method. Among the most commonly used light sources in the industry are:

- incandescent bulbs,

- fluorescent tubes,

- sodium lamps,

- metal halide lamps,

- induction lamps,

- LED lamps.

Mercury light sources, due to their harmfulness, have been discontinued from production and are not considered in further analysis. On the other hand, fluorescent lamps, which are withdrawn from sale in the EU, are still used in many places worldwide, including Europe.

Each light source is characterized by specific physical parameters resulting from the technology used. Knowledge of these parameters and temperature conditions allows for assessing whether the selected light source will operate efficiently, avoid premature degradation, and be economically justified for use.

To assess which light source best meets our needs, below we present their advantages and disadvantages.

| Light source | Advantages | Disadvantages |

| Traditional bulb (vacuum, gas) / Halogen | Exceptional resistance to temperature changes, Efficient operation across a range of temperatures from negative to positive, Excellent color rendering in various ambient temperatures. | Low luminous efficiency: 15 lm/W for incandescent, up to 35 lm/W for halogen, Short lifespan: 1000 hours for incandescent, 3000 hours for halogen, High filament operating temperature (2500°C), bulb around 80–150°C. |

| Linear / Compact fluorescent lamp | High resistance to temperature changes within positive values, Acceptable on-off operation in positive temperatures, Good color rendering over a wide range of temperatures. | Moderate luminous efficiency: 40–100 lm/W and lifespan: up to 15,000 hours for T8, 25,000 hours for T5, Poor resistance to low temperatures – reduction in light output, Requires an ignition system. Solutions for using fluorescent lamps in low temperatures: Special design (housing) of the fluorescent tube, Housing made of polymethyl methacrylate (PMMA), Shield creating a layer with low thermal conductivity, Increasing temperature to support the chemical ionization of the gas, Enhancing luminous efficiency through the use of mercury vapor between the electrodes in the tube. |

| High-pressure sodium lamps | Very high luminous efficiency: 200 lm/W and long lifespan: up to 30,000 h, Excellent resistance to temperature changes in both negative and positive ranges, Minimal light output drop over time and excellent contrast. | Poor resistance to low temperatures during ignition, Long ignition time in negative ambient temperatures (up to 5 minutes), Issues with re-ignition (unsuitable for emergency lighting), Low color rendering index Ra < 40. |

| Low-pressure sodium lamps | Very high luminous efficiency: 200 lm/W and good lifespan: up to 20,000 h, Excellent resistance to temperature changes, Minimal light output drop during operation, Ignition possible at very low temperatures (up to –50°C). | Very long ignition time (up to 10 minutes at low temperatures), Issues with re-ignition (unsuitable for emergency lighting), Very low color rendering index Ra < 20. |

| Metal halide lamps | Good luminous efficiency: 100 lm/W and good lifespan: up to 20,000 h, Excellent resistance to temperature changes, Minimal light output drop during use, Good color rendering index Ra < 80. | Poor resistance to low temperatures during ignition, Long ignition time, especially at low temperatures, Issues with re-ignition, Requires a special ignition system. |

| Induction lamps | Very high luminous efficiency: about 120 lm/W and long lifespan: 60,000 to 100,000 h, Excellent resistance to temperature changes, Minimal light output drop, Good color rendering index Ra > 80, Quick start and reaching nominal operating parameters. | High investment cost, Difficult ignition using high-frequency generator. |

| LED sources | Very high luminous efficiency: up to 220 lm/W and long lifespan: 50,000 to 200,000 h, Excellent resistance to low temperatures, Minimal light output drop during operation, Good color rendering index ranging from Ra = 70 to Ra = 90, Full control of light intensity using various methods. | Moderately high investment cost, dependent on product quality, Degradation of the junction during operation at high temperatures, which may shorten lifespan, Requires a special constant voltage or constant current power supply. |

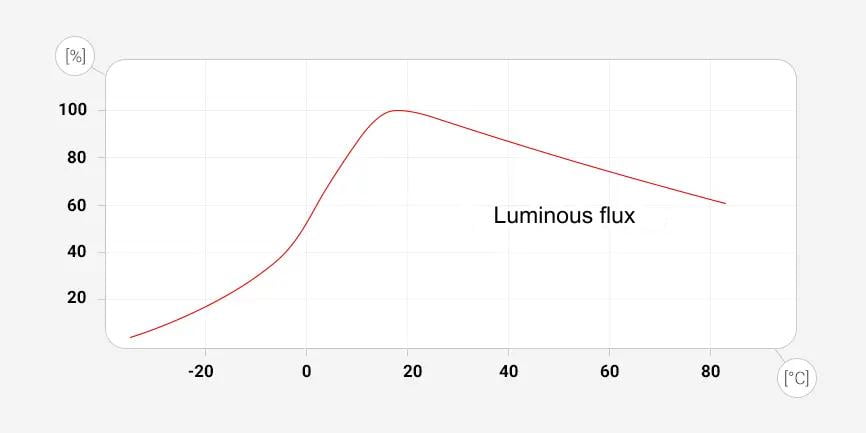

Fluorescent lamps: not for low temperatures

Due to the significant drop in light output at low temperatures (as shown in Figure 1), standard fluorescent lamps are not used outdoors (climatic zones where negative temperatures occur) or in cold storage facilities.

How to improve LED performance in high temperature?

To optimize the operating conditions of an LED light source, effective heat dissipation is key. This can be achieved by using specially designed housing and pin radiators, which are more efficient than previously used methods.

The material used for the housing and additional radiator should be made from dense cast aluminum, which, thanks to its uniform material structure, allows for rapid heat dissipation. The quality of this material can be assessed by its weight – the heavier, the better the thermal properties.

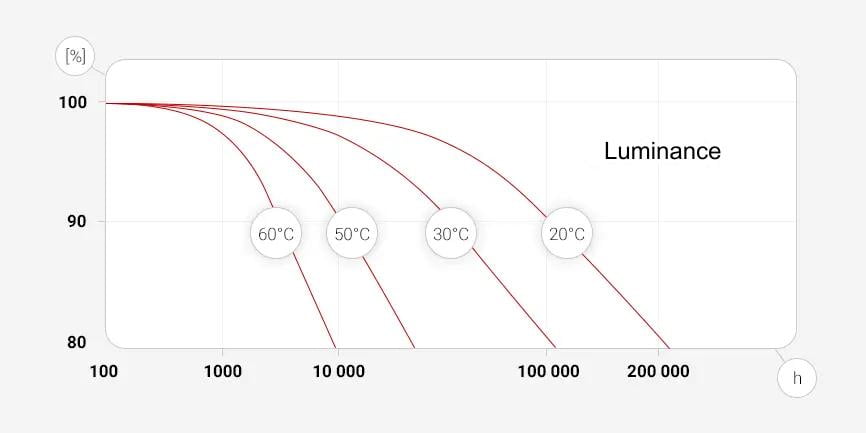

Note: An increase in the junction temperature of the LED by 20°C can lead to a sixfold reduction in the device’s operating time under nominal parameters. LED luminance decreases with rising temperature, as clearly shown in Figure 2, illustrating junction degradation due to temperature rise. This significantly limits the lifespan of the light source.

High temperatures inside the lighting fixture can lead to damage to silicone lenses, causing their mechanical destruction. It is important to consider the impact of external factors during installation. Fixtures should also be kept away from additional heat sources, which can disrupt or intensify the cooling process. This applies to both natural heat sources, such as sunlight, and artificial ones, such as installations generating high temperatures during production processes.

The most effective way to improve the performance of an LED light source is to rapidly dissipate the heat generated during diode operation. This can be achieved using a PCB with an aluminum layer, which has good thermal conductivity and directly dissipates heat from the soldered LED. The PCB consists of an aluminum plate with a thickness of 1 to 3 mm, covered with a ceramic insulating layer, on which copper power tracks are placed. The whole assembly is often connected to an additional radiator or housing using thermal paste, which increases the surface area for heat dissipation.

In situations where the LED light source, along with the PCB, radiator, and power supply, is housed in a linear fixture, exposing it to significant internal and external temperature fluctuations, it becomes crucial to use a special vent plug. This plug ensures proper ventilation and equalizes pressure between the interior and the external environment, preventing condensation. Additionally, it protects against temperature increases that may occur due to intense sunlight heating the interior of the fixture. Special caps or plugs are used at the installation points of these vent plugs to introduce power cables into the fixture.

Temperature resistance of the power supply system

To effectively generate light output from selected light sources, it is necessary to appropriately select power supply systems that provide optimal electrical and lighting results. In the case of LED sources, the biggest challenge is often the ballast, or power supply system, which affects the overall reliability of the fixture. Its lifespan is critical and often determines the longevity of the entire fixture.

One of the key issues in power supply systems is the resistance of electronic components, particularly capacitors and copper tracks, to high temperatures. Capacitor drying, which accounts for about 80% of failures, leads to a loss of proper filtration and energy storage capacity, affecting the power supply’s operation. The choice of capacitor often involves a compromise between cost and quality, and in the case of power supplies, capacitors along with magnetic components are typically the most expensive components.

High temperatures inside the fixture, exceeding the maximum permissible values for power supplies, and the transfer of heat from the light source to the power supply system via the PCB can lead to the evaporation of the electrolyte from capacitors. The long-term and reliable operation of the entire fixture thus depends on the quality and durability of the electronic components used.

Efficiency and durability of power supply systems and batteries in various temperatures

According to the Arrhenius theory, the lifespan of an aluminum capacitor doubles every time the ambient temperature drops by 10°C. Separating the electronics system from the radiator can yield better results than mounting it in an integrated housing. Some manufacturers, aiming to increase efficiency, use two or three power supplies for a single lighting unit, which reduces the load and overheating of internal components, minimizing the risk of degradation and failure.

Battery temperature resistance

For emergency power supply, in accordance with fire protection regulations and building codes, it is required to provide lighting within 0.5 seconds for high-risk areas, as well as 50% lighting intensity within 5 seconds and 100% within 60 seconds for escape routes and anti-panic zones. Emergency power supply is often realized through:

- battery modules with a power supply unit placed inside the fixture,

- backup power installation with a central 220V DC battery.

In both cases, the lifespan of batteries, as energy storage sources, is greatly influenced by temperature. Each increase in temperature by 10°C above the normative 20°C halves the lifespan of the battery cell. A battery placed inside a fixture, which is typically designed to last 4 years, will operate according to its parameters for only half a year at an ambient temperature of 50°C. A stationary battery, designed for 10 years according to EUROBAT standards, will show a lifespan of 5 years at a temperature of 30°C. It is also important to note that low temperatures also negatively impact battery lifespan.

Issues with battery energy efficiency

Due to physicochemical processes, the energy stored in batteries is sometimes not fully utilized, which in the case of damaged cells can lead to a lack of voltage supply to the power supply and a complete lack of lighting.

An important factor affecting battery lifespan is also sudden temperature changes. The amount of energy that can be extracted from a battery depends on its temperature, which means that temperature differences in the summer and winter seasons can reduce the available energy by up to half.

When selecting battery capacity for the power of the light sources it will power, this dependency should be considered. In some cases, it may be necessary to oversize the battery to ensure its proper functioning in a given installation.

Additionally, the risk of undercharging the battery to full capacity and degradation of its internal structure should be considered. In such situations, both the capacity and efficiency of the battery may be proportionally reduced, affecting the efficiency and reliability of the entire emergency power system.

Electrochemical processes inside a battery

The course of chemical reactions inside a battery cell can slow down due to an increase in internal resistance, resulting in slower chemical reactions. This phenomenon is also important in the context of other light sources, such as photoluminescent lamps, which may not reach the expected light parameters at higher current draw or may even stop functioning altogether.

Power outages pose a serious threat, potentially leading to deep discharge and battery damage. Prolonged power outages, resulting in incomplete discharge and charging, are less harmful to systems with longer operating times, e.g., 3 hours, than to those with shorter ones, such as 1.5 hours.

The weakest cell determines the condition of the entire battery pack, so it is crucial to maintain all cells in the best possible condition. Regular manual or automatic checking of the status allows for a quick assessment of the entire pack’s condition.

During battery discharge, it is important to remember the temperature at which this process occurs, and the devices performing this task should be equipped with systems that regulate the charging and discharging current. Reference hysteresis curves are often used to maintain the current at the appropriate level and avoid exceeding the nominal capacity. The 1C designation refers to the so-called one-hour current, used to determine the charging rate of a battery. Different types of batteries react to temperature differently; they may be undercharged, reducing their efficiency, or overcharged, which can lead to danger, including the risk of cell explosion.